Understanding UV LED Technology

An Introduction into UV LED Systems

Forty years ago, mercury-based arc lamps were the only UV light source available to initiate the UV curing process. New bulb-based light sources such as Excimer bulbs, microwave sources have been introduced, but the basic technology remains the same.

In 2002, Phoseon Technology developed a “bulbless” LED based technology to produce UV light for curing applications. Phoseon Technology’s patented Semiconductor Light Matrix (SLM)™ technology combines LEDs, arrays, optics and cooling to deliver the most sustainable, coolest operating, highly efficient ultraviolet curing products on the market.

What is UV curing?

Ultraviolet (UV) curing is a photopolymerization process that uses UV energy to change a liquid to a solid. Upon absorption of the UV energy, the photo-initiators produce free radicals which initiate cross-linking with binders (monomers and oligomers) in a polymerization reaction to cure or solidify the ink, coating or adhesive. UV formulations also incorporate various additives such as stabilizers, wetting agents, adhesion promoters, defoamers and pigments to provide desirable characteristics or color of the cured material.

What is a UV LED?

Ultraviolet (UV) LED stands for ultraviolet light emitting diode. A UV LED is an electronic light source with electromagnetic radiation that has a wavelength shorter than that of visible light but longer than x-rays.

UV Light Emitting Diodes (LEDs) are a solid-state device that produces light when an electrical current is allowed to flow from the positive (p-type or anode) side of the circuit to the negative (n-type or cathode) side. This is called the ‘p-n junction’. Each LED is made to produce a specific narrow range of UV wavelength.

Expected lifetime of the UV LED light sources

As a result of Phoseon’s rigorous reliability efforts, lifetime testing of light sources has now surpassed 60,000 hours of operational on-time with light source irradiance being greater than 80% of its original output when the test first began five-plus years ago. For perspective, utilizing a single shift workweek of 2,000 hours per year, 60,000 hours equates to 30 years of UV LED operating on-time.

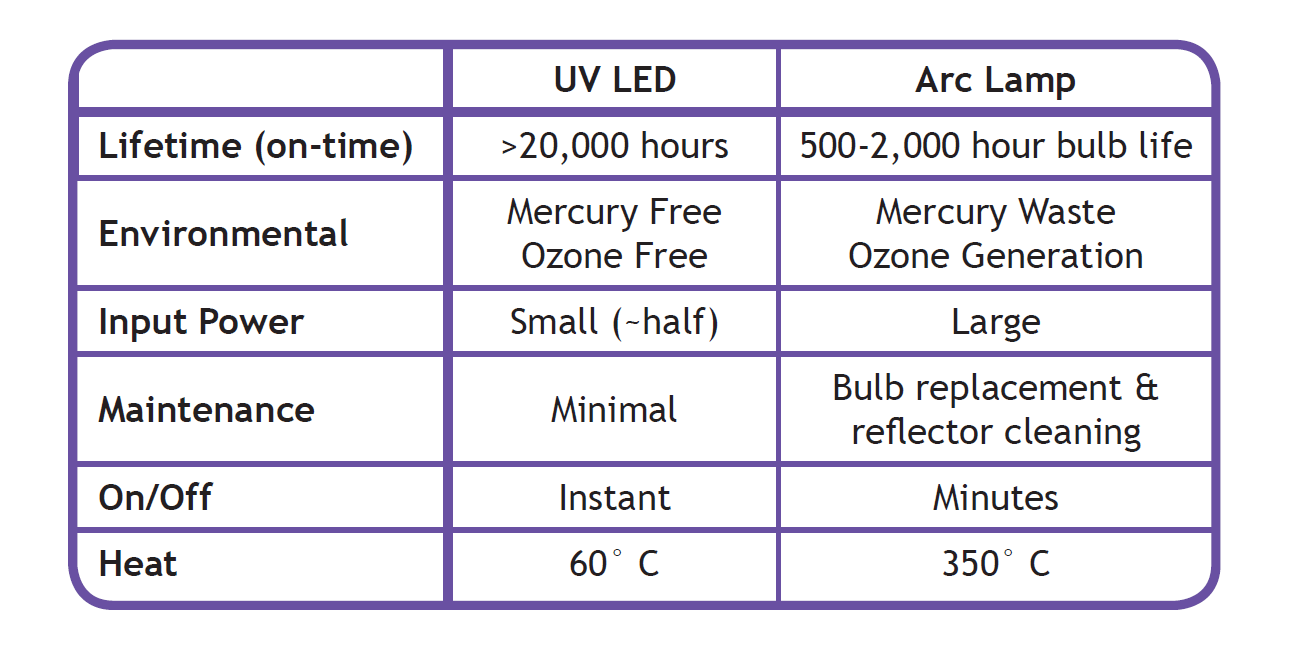

The difference between traditional UV lamps and UV LED sources

Traditional Arc lamps use an electric arc inside a mercury gas to excite atoms, which then decay, emitting photons. An arc lamp or arc light is the general term for a class of lamps that produce light by an electric arc. An arc lamp is also called a discharge lamp, or an arc discharge lamp. The type of lamp is often named by the gas contained in the bulb; including neon, argon, xenon, krypton, sodium, metal halide, and mercury. The common fluorescent lamp is actually a low-pressure mercury arc lamp. Microwave lamps excite the gas via microwave emission. Xenon lamps use Xenon gas (no mercury) but can only be “flashed.” UV LED Semiconductors (UV LED) emit a narrow bandwidth of light at the junction where doped semiconductor positive holes join with negative electrons when voltage is applied.

What application markets does Phoseon’s LED technology support?

Phoseon products are currently used in both Industrial Curing applications for UV LED curing of printing, coatings and adhesives, as well as Life Sciences solutions for biological inactivation, molecular detection, and advanced imaging.

How does the SLM technology differ from other UV LED solutions available on the market?

Phoseon’s proprietary Semiconductor Light Matrix (SLM) technology produces significantly higher intensity light than other LED UV curing technologies. The light produced by traditional UV LEDs is limited by the discretely packaged design. Phoseon’s SLM approach is to use proprietary packaging, optics, and thermal design to optimize the output.

Can I use my existing UV curable materials?

UV materials must be formulated to use photoinitiators that are sensitive to the narrow wavelength range provided by UV LED. Phoseon works with the major UV material manufacturers to ensure their products are formulated correctly, and most now offer UV LED compatible products. Contact your provider for more information.

How do you select a UV LED supplier?

if you are interested in utilizing UV LED curing technology, it is important to take a closer look at the company capabilities and reputation of the UV LED supplier. It is also important to contrast and compare the differences in performance of the various UV LED based systems. After learning all the facts, you can then quantitatively determine that not all UV LED curing suppliers or systems are created equally. For more information on UV LED curing explore Phoseon’s FAQ section for common questions, and throughout answers: https://phoseon.com/industrial-curing/resources/faq-glossary/