SICPA: Expanding Applications Latitude with Thermal Inkjet

Non-impact printing technologies are the most suitable for a variety of industry applications.

The lack of contact between the print actuator and the support represents a significant advantage, for example, in case of printing on moving objects, as occurs during the coding and marking of packaged products in serialisation lines.

Developments in Microfluidics as well as ink formulations targeted to meet specific needs have enabled the application of this technology on a wide variety of substrates, even and especially on non-porous materials, ensuring both the printing quality and the level of resistance required by the performance standards.

This synergy, in many cases, avoids any further application of a protective, transparent coating layer onto the printed surface. Therefore, it is possible to produce simpler and less expensive printing systems, suitable for non-porous media, while maintaining high-level performances.

With respect to the piezo inkjet print heads, which are largely used for non-impact industrial printing, the thermal inkjet devices (also named “bubble jet”) represents a lower total cost of ownership for certain industrial and specialty applications, requiring easy user maintenance and a compact size of the hardware device without compromising the highest standards in quality and reliability.

The interaction between the ink and print head, which is a critical factor in thermal inkjet, has been constantly optimised over time and together with the enhancement of ink formulations, more and more reliable materials have been developed. This constant improvement allowed the new inks to better match both the functional behaviour and the printing performance of the device.

Unquestionably, the combination of “thermal inkjet print head + ink” can be considered a rugged and reliable printing device nowadays as the thermal technology is able to replace the piezo technology in a great number of implementations with excellent results.

In fact, where allowed by the application, the replacement of piezo actuators with thermal inkjet print heads is already being broadly accomplished in the industrial installations. Such replacement is driven by the need of cost reduction and sustained by the high quality and reliability standards, already well established, making thermal inkjet a sound and cost-effective solution for the industrial printing business as well.

THERMAL INKJET TECHNOLOGY AT SICPA

Product development at SICPA takes advantage of the combined efforts of two major R&D expertise:

· Print head design and development

· Ink study and formulation

The synergic work between the two departments results in the solid optimisation of the printing device: the ink, whose formulation complies with the requests of specific applications, is ejected by a print head, that is designed and intended to exploit and enhance the ink performances. In the print head design, many parameters play a role, such as:

· Ink boiling characteristics and rheology

· Required drop volume

· Printing resolution

· Maximum ejection repetition rate

which are among the most significant ones.

Through the print head design, the functional parameters are defined. To go further into detail, the shape and size of both the fluidic circuit and the resistors are laid down and the energy variables, such as current peak value and pulse duration, are decided. Moreover, the operational temperature of the print actuator is defined by design and effectively controlled through a suitable circuitry, according to the working conditions.

Thermal inkjet printhead

By means of the numeric simulation, it is possible to follow the vapor bubble evolution in all its phases: generation, expansion accompanied by ink ejection from the nozzle, collapse and finally, ink refilling of the ejection chamber. Therefore, the working parameters of the print head can be assessed and optimised with respect to the ink characteristics, the latter being in turn, dictated by the actual application.

Bubble evolution in time - Simulation of bubble volume (blue) and pressure

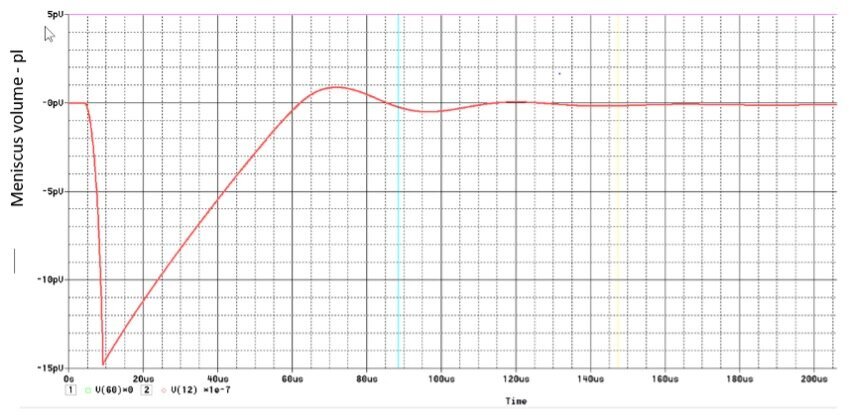

Nozzle refilling - Simulation of the meniscus movement from bubble collapse to stabilisation. Damped oscillations are visible at the end of the refilling time interval

Such an integration between ink and print head in view of the application allows the user to achieve high level performances, which are not accessible utilising mass market cartridges filled with non-original inks: they are invariably bound to fail to meet quality standards, due to their unoptimised functioning. As a result, moving towards an integrated printing system, such as that offered by SICPA, represents a real breakthrough in industrial activity.

THERMAL INKJET PRINT HEADS PORTFOLIO

The Thermal Inkjet print heads, designed and developed by SICPA, may be divided into two macro-groups, having different cartridge sizes:

· Monochrome print head (swath length 1”)

· Trichrome print head (swath length 2/3”)

The printing resolution, expressed in dots-per inch or dpi, and the dot size depends on both the layout and the nozzle diameter as well as on the print head driving mode. Thus, the horizontal and vertical resolution can be effectively managed, according to the drop volume, the ink type and the medium characteristics.

At present, what SICPA offers consists of a portfolio of well-established products; however, it should be pointed out that the modular architecture of the printing actuator allows the designers to customise both the ejector layout and the microfluidic circuit, without having to completely redesign the device’s underlying electronics. Such flexibility makes it possible to broaden on demand and provided there is a business justification, the area of use. Hence, the requirements of a specific scope can also be satisfied by a targeted print head.

The monochrome print head TYCHE has a swath length over 1” and a printing resolution up to 600x600 dpi, even though certain applications can take advantage of a printing mode performed at a lower resolution.

The portfolio will be expanded with a TYCHE print head with high volume drops (about 30 picolitres) and a printing resolution up to 300x300 dpi.

The trichrome print head CROMA has instead a swath length of 2/3” and a printing resolution up to 1200x600 dpi; here too it may be convenient to reduce the actual printing resolution for certain applications. CROMA is available in two versions with solvent ink and one version with water ink.

THE ADDED VALUE PROVIDED BY THE INKS

The inks for the bubble jet print heads that have been developed by SICPA to date, can be classified in two groups:

Water-based inks

Water is the main vehicle in these formulations, which may also contain dyes and/or pigments. They have been developed for printing on both porous and semi-porous media; water inks are widely used for printing onto secondary and tertiary packages in the pharmaceuticals industry.

Solvent-based inks

The vehicle for dyestuffs of pigments is formed in this case by mixtures of various solvents, that are suitably selected and put in the right proportion, in order to meet at best both the functionality and the adhesion strength on the substrate. Solvent inks have been developed for printing onto non-porous plastic media (PVC, PET, PE, PC, etc.) and they found successful to use for the badge printing, often adopted as identification cards by companies or as membership cards by stores.

INNOVATION NEVER STOPS: WATER BASED UV CURABLE INKS FOR THERMAL INKJET

The possibility to provide suitable solutions for covering a broad range of industrial applications, that water inks could not access for a long time, has raised a great interest right away. Among them, printing on plastic and metal surfaces, coding & marking on pharmaceutical packages are the most attractive.

Hence, SICPA initiated a project to study and develop a family of water-based inks, which can be cured using suitable UV LED lamps.

It is well known that the most outstanding elements, which can hinder the adoption of the traditional water inks with non-porous media, turn out to be:

· Long drying time

· Low adhesion strength to substrate and, in turn, short printout durability

· Poor resistance to water and solvent exposure

Introducing the UV curing method and implementing it with water-based formulations lead to address all the critical characteristics of the traditional inks, providing:

· Drying time consistent with the application requirements, i.e. lesser than 3 seconds

· High adhesion to plastic and metal surfaces, demonstrated by the abrasion resistance values: up to 5 times as high as that of the solvent inks, taken as a benchmark

· Strong resistance to contact, immersion and rubbing with water and common solvents

It must be emphasised that the use of water-based UV inks within the industrial printing activities leads to a dramatical decrease in the presence of organic volatile compounds (VOC) in the production lines, with obvious advantages in terms of Health and Safety for operators and environment.

Some examples of printouts obtained with SICPA water-based UV curable inks are illustrated below:

Many other interesting aspects could be described in more detail, but this short review can already describe the capabilities of the digital printing solutions provided by SICPA Thermal Inkjet technologies.

As a sponsor of the upcoming FuturePrint Tech Fest, SICPA will be giving a 30-minute presentation on 29-30 June 2021 where we will be discussing more of our Thermal Inkjet Printing Solutions.

Register for SICPA’s Tech Fest session, ‘Developing New Solutions For Digital Printing Through Innovation And Strong OEM Partnerships’, here.

For information on SICPA, please contact:

Roberta Sirio

B2B Sales Director, SICPA SA